- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

You can find tinplate sheets in many places, like food cans and paint buckets. These sheets are made by mixing steel and tin. This makes them strong and stops them from rusting. Many businesses use tinplate to pack things.

In 2023, people used over 12.43 million tons of tinplate just for food and drink cans. This shows how important tinplate is in our lives.

| Property | Description |

|---|---|

| Durability | Has the strength of steel and does not rust easily because of tin. |

| Corrosion Resistance | The tin layer keeps the metal from rusting, even when it is wet or dirty. |

| Versatility | Used in many areas, like food, drinks, and even airplanes. |

| Recyclability | It is simple to recycle, so it helps the environment. |

A printed tinplate sheet looks nice and works well. The way companies make and print these sheets gives you good quality and many uses.

Tinplate sheets are tough and do not rust easily. This makes them great for food packaging and factories. The smooth surface of tinplate is good for bright printing. This helps people see products better and makes brands look nicer. Tinplate can be recycled many times. This helps the environment and cuts down on trash. Picking the right coating weight and temper grade is very important. It helps tinplate products last longer and work well. Tinplate sheets can be used in many ways. They are used for food cans and car parts. They help keep things safe and protected.

You might wonder what makes a tinplate sheet so special. A tinplate sheet is a thin, flat piece of steel coated with a layer of tin on both sides. This process uses low-carbon steel, which gives the sheet its strength. The tin coating protects the steel from rust and makes the surface smooth and shiny. Manufacturers like Hengyu Can use strict standards to keep impurities low in the steel. This helps the tinplate sheet resist corrosion and last longer. The tin layer is very thin, usually between 0.0003 and 0.0008 inches. You can find different surface finishes, such as bright, stone, silver, or matte. Each finish gives the tinplate sheet a unique look and feel.

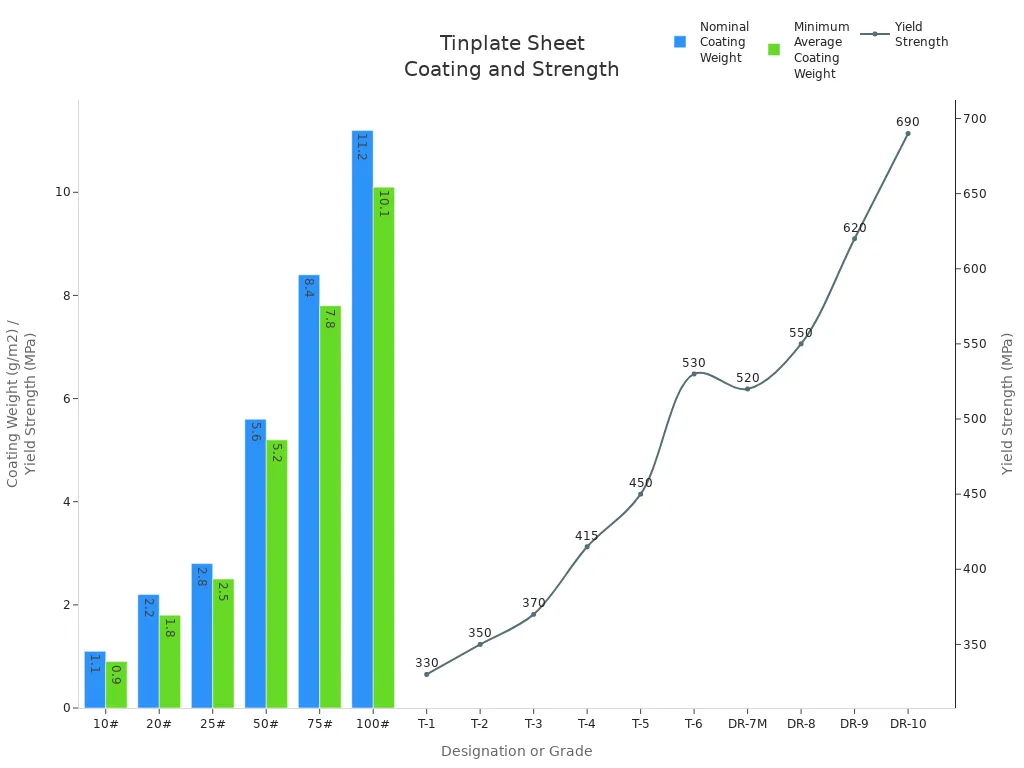

The industry uses several coating weights and temper grades to match different needs. Here is a table that shows some common coating weights and hardness levels:

| Coating Weight Designation | Nominal Coating Weight (g/m2) | Minimum Average Coating Weight (g/m2) |

|---|---|---|

| 10# | 1.1/1.1 | 0.9/0.9 |

| 20# | 2.2/2.2 | 1.8/1.8 |

| 25# | 2.8/2.8 | 2.5/2.5 |

| 50# | 5.6/5.6 | 5.2/5.2 |

| 75# | 8.4/8.4 | 7.8/7.8 |

| 100# | 11.2/11.2 | 10.1/10.1 |

| Temper Grade | Hardness (HR30Tm) | Yield Strength (MPa) |

|---|---|---|

| T-1 | 49±3 | 330 |

| T-2 | 53±3 | 350 |

| T-3 | 57±3 | 370 |

| T-4 | 61±3 | 415 |

| T-5 | 65±3 | 450 |

| T-6 | 70±3 | 530 |

| DR-7M | 71±5 | 520 |

| DR-8 | 73±5 | 550 |

| DR-9 | 76±5 | 620 |

| DR-10 | 80±5 | 690 |

A tinplate sheet stands out because of its unique mix of features. Here are some key properties you should know:

Strength and Hardness: The steel core gives the tinplate sheet its strength. Different temper grades let you choose the right hardness for your needs.

Corrosion Resistance: The tin coating keeps moisture and air away from the steel. This helps prevent rust, even in wet or dirty places.

Printability: You can print bright, colorful designs on a tinplate sheet. The smooth surface makes it easy to add labels or logos.

Workability: Tinplate sheets bend and shape easily. You can use them to make cans, boxes, or other containers.

Food Safety: Tinplate is nontoxic. It keeps food safe and fresh by blocking moisture and gases.

Heat Resistance: You can use a tinplate sheet for products that need high temperatures, like sterilized food cans.

Magnetic Properties: Tinplate sheets are magnetic. This makes recycling and sorting simple.

Tip: When you choose a tinplate sheet, think about the coating weight and temper grade. These factors affect how strong and durable your product will be.

A tinplate sheet gives you a strong, safe, and flexible material for many uses. You can rely on it for packaging, storage, and more.

Making tinplate sheets takes many steps. Each step helps make the sheet strong and smooth. You start with raw materials. The finished sheet is ready for printing and many uses.

First, you pick good raw materials. Steel is the main material for tinplate sheets. Low-carbon steel gives the sheet strength and lets it bend. Companies like Hengyu Can use strict rules to keep steel clean. This helps the sheet last longer and stops rust.

Steelmaking is the first step. You melt iron ore and other things in a blast furnace. You add fluxes to take out bad stuff. The melted steel is poured into slabs. Next, you heat the slabs and roll them into thin sheets. This is called hot rolling. Hot rolling shapes the steel and makes it better.

After hot rolling, you do cold rolling. Cold rolling makes the sheet even thinner and smoother. It also makes the sheet harder and stronger. You must watch the process closely. Here are some ways to check quality:

You watch the tin content to stop rust and dirt.

You keep the furnace air just right for tin.

You use special materials to catch tin well.

You check how much the pinch rollers wear down.

You change pinch rollers often to keep the right shape.

You use tools to check the space between rollers.

You make sure the rollers are flat and even.

You look for wear on the roller’s surface.

You change the roll gap if needed to keep things steady.

These steps help make a good steel sheet. The process makes sure the sheet is the right thickness, hardness, and smoothness.

Note: Good control during steelmaking and rolling stops problems and makes a better sheet.

After rolling, you add a coating. This step is very important. You cover both sides of the steel sheet with tin. The tin keeps the steel from rusting and makes it shiny.

You can pick different coating thicknesses for different jobs. Here is a table that shows common coating thicknesses:

| Coating Type | Thickness Range (μm) |

|---|---|

| Electronics & Packaging | 1 - 5 |

| Industrial Corrosion Protection | Up to 20 |

You must follow strict rules for coating thickness. ISO 9001 helps keep the process the same every time. You check each step, from picking materials to shipping the sheet. This makes sure the coating is even and smooth.

Special coatings are made for special jobs. Experts can change coatings and glues for the best results. Good coatings make the sheet last longer and work better.

The coating also changes how printing looks. You need strong inks because the sheet is smooth and hard. The way you coat and varnish can make prints last longer and look nicer. Good ink is important for bright and strong prints on tinplate sheets.

Tip: Always check the coating thickness and evenness. This helps your product last longer and look nicer.

Before printing, you must get the surface ready. This step is very important. It helps the ink stick and makes prints look good.

There are different ways to clean the surface. Here is a table that shows some methods:

| Technique | Description |

|---|---|

| Mechanical Cleaning | Uses blasting, brushing, or grinding to take off dirt. |

| Chemical Cleaning | Uses solvents, acids, or alkalis to clean, then rinses. |

| Electrochemical Cleaning | Uses electric current to clean and help ink stick. |

The surface must be very clean. If it is dirty or rough, ink will not stick well. This can make prints look bad or colors uneven. Clean surfaces help prints look bright and last longer.

You must be careful with every part of cleaning. This step gets the tinplate sheet ready for printing and other uses. The process is not done without good surface cleaning.

Remember: Clean surfaces make prints better and the final sheet higher quality.

Making tinplate sheets is a long process but very important. You start with raw materials, shape and roll the steel, add a coating, and clean the surface for printing. Each step helps make a strong and useful sheet for many jobs.

Tinplate sheet printing lets you put bright designs on metal packages. You see this on food cans, paint buckets, and other things at home. The printing uses special steps to make sure your product looks good and lasts long. Hengyu Can uses new machines and strict rules for every tinplate sheet printing job.

Offset printing is the main way to print on tinplate. This method gives clear pictures and even colors. It works well for big batches and gives the same results each time.

Here are the main steps for offset printing on tinplate sheets:

First, you make a printing plate with a special coating.

Next, you put your design on the plate using a digital image.

Then, you shine light on the plate. The coating gets hard where the image is.

You wash off the soft parts. This leaves a raised picture on the plate.

You put the plate on a press and add wet ink.

Rollers move the ink from the plate to a rubber blanket.

The rubber blanket puts the inked image on the tinplate sheet.

The printed tinplate sheet dries.

Offset printing has many good points for tinplate sheets:

You get sharp and detailed pictures.

It saves money when you print a lot.

You can print on many materials, like tinplate sheets.

The colors stay the same and look right.

The process is quick for big jobs.

Prints last long and do not fade or wear out.

Hengyu Can uses modern presses that print tinplate sheets very well. Their machines control ink and pressure to stop smudges or bad colors. You can trust their work for small or big orders.

Tip: Offset printing lets you put hard designs and logos on tinplate sheets. Your products look neat and professional.

Sometimes, tinplate printing has problems. Here is a table with common problems and how to fix them:

| Challenge | Solution |

|---|---|

| Ink adhesion | White the tinplate before printing to improve ink adhesion. |

| Requirements for white ink | Print white twice to achieve 75% whiteness; use a primer to enhance bonding with white ink. |

| Requirements for color ink | Use thermoset ink with heat resistance and good adhesion properties. |

| Ink drying process | Control drying speed to avoid issues like weak imprinting or overprinting difficulties. |

Hengyu Can fixes these problems by using special primers and inks that can take heat. Their way keeps tinplate sheet printing bright and strong, even after a long time.

Color separation is an important step in tinplate sheet printing. You break your design into different colors so each one prints by itself. This helps you get the right colors and clear pictures on your tinplate sheets.

You use computers to split colors in your artwork. Each color gets its own plate. This makes sure every part of your design shows up on the tinplate sheet. If you skip this, your product may not look like your design.

Proofing comes next. You check the color film and see if it looks right. You compare the proof to your customer’s sample to make sure the colors and details match. Hengyu Can uses new proofing tools to catch mistakes before printing starts.

Color separation is needed for good tinplate printing.

Old ways can make the printed tinplate sheet look different from your design.

Proofing helps you find mistakes and fix them before printing a lot.

You check the drawing and say yes to the proof before printing many tinplate sheets. This step saves you time and money by stopping big mistakes.

Note: Always look at your proof closely. Small color mistakes can cause big problems in the end.

Hengyu Can’s proofing uses high-quality scanners and color software. You see a preview of your tinplate printing before it starts. This helps you get the look you want for your package.

Ink curing is the last step in tinplate sheet printing. You need to dry and set the ink so it stays on the tinplate sheet. The printing uses heat to make sure your prints last.

Here is a table that shows how ink curing works:

| Ink Curing Method | Temperature Range | Curing Time | Effects on Durability and Resistance |

|---|---|---|---|

| Heat Curing | 130–150°C | 10–12 minutes | Ensures proper fixation and enhances durability; prevents discoloration of pigments and binders. |

You put the printed tinplate sheet in a hot oven. The heat makes the ink stick to the metal. This step keeps your design from fading or peeling. You must dry the ink at the right speed to stop problems like weak prints.

Inks must handle high heat during curing.

Drying at the right speed stops fading and sticking problems.

The ink should keep its color and work well under heat.

Hengyu Can uses ovens with good temperature controls. Their way makes sure every tinplate sheet printing job is strong and lasts long. You get prints that stay bright, even after storage or rough use.

Tip: Always pick inks made for tinplate printing. These inks can take heat and keep your designs looking new.

You can see better quality when you cure ink the right way. Your tinplate printing will last longer and look nicer. Hengyu Can’s curing helps you meet safety and packaging rules.

Hengyu Can is a leader in tinplate sheet printing. You get help from their new offset machines, careful checks, and custom choices. Their products cover many coating weights, temper grades, and finishes.

Here is a table that compares Hengyu Can’s tinplate printing specs:

| Specification | Hengyu Can Standard | Industry Average |

|---|---|---|

| Coating Weight | 1.1–11.2 g/m² | 1.0–10.0 g/m² |

| Temper Grade | T-1 to DR-10 | T-1 to DR-9 |

| Surface Finish | Bright, Stone, Matte | Bright, Matte |

| Printing Resolution | Up to 2400 dpi | Up to 1800 dpi |

| Ink Type | Thermoset, UV | Thermoset |

| Proofing Technology | Digital, Film | Film |

You get more options and better quality with Hengyu Can. Their tinplate sheet printing uses high-resolution plates and good color separation. You can order special sizes and finishes for your needs.

Note: Hengyu Can’s tinplate printing meets ISO 9001 rules. You can trust their products for food safety and long use.

You see Hengyu Can’s tinplate sheet printing in many places. Their products are in food cans, paint buckets, and fancy tins. You get strong performance and nice designs every time.

There are new trends in tinplate printing. Companies now use inks and coatings that are better for the planet. Digital printing lets you get faster jobs and more detailed designs. Hengyu Can uses green methods and digital tools to stay ahead.

Eco-friendly inks help the environment.

Digital printing gives more choices for custom jobs.

High-resolution printing makes brands stand out.

You can pick tinplate sheet printing for small or big projects. The printing can change to fit your needs, from simple labels to hard artwork.

Tip: Ask your supplier about new printing tools. You might find ways to save time and get better quality.

Tinplate sheet printing gives you a strong, bright, and safe way to pack your products. You get tough prints, bright colors, and good results. Hengyu Can’s printing helps your products get noticed.

Tinplate sheet is used in many parts of life and work. You can find it in food packaging, things at home, and in factories. Tinplate sheet is picked because it does not rust, you can print on it, and it keeps things safe.

Most food cans are made from tinplate sheet. These cans keep food fresh and safe to eat. Tinplate stops rust and keeps food from going bad. It blocks light, air, and water from getting in. This helps food taste good and last longer. The cans close tightly, so germs cannot get inside. Tinplate is safe and does not let bad chemicals touch your food. You can print bright labels and clear words on these cans. The printing looks sharp and the colors are strong. Brands use tin can printing to stand out in stores. Tinplate sheet is trusted for food cans because it follows safety rules.

Tinplate stops rust and keeps food safe.

It keeps food fresh for a long time.

Tight lids stop germs from getting in.

You can print clear labels for brands.

Tinplate sheet is used for many things at home. You see it in cans for food, drinks, and art supplies. It is also used for buckets that hold many things. Tinplate is strong and easy to print on. It is good for fancy foods and makeup. The shiny look helps brands, and it is easy to recycle because it is magnetic. Tinplate is also used in small machines and kitchen tools. Printing on these cans makes them look nice and gives you information. You can pick different designs for each product.

| Household Goods | Description |

|---|---|

| Food Cans | Used to pack many kinds of food |

| Beverage Cans | Made for drinks and sodas |

| Artistic Cans | Fancy cans for art supplies |

| Crude Buckets | Used to store and move things |

| Petroleum Buckets | Hold oil and other liquids |

Factories use tinplate sheet in many ways. It protects things from rust in tough places. In packaging, tinplate is used for cans, lids, and tops. Cars use tinplate for oil filters and battery covers. Builders use it for roofs, walls, and wires. Electronics use tinplate for boards and heat sinks. You can print labels and logos on tinplate, even for factory products. Chemical cans use tinplate because it is strong and safe. Printing on these cans keeps safety and product details easy to see. Tinplate sheet gives you strong and lasting protection.

| Sector | Products |

|---|---|

| Packaging | Food cans, spray cans, lids, and tops |

| Automotive | Oil filters, gaskets, battery covers, trim |

| Construction | Ducts, shelves, sheds, wire covers |

| Electronics | Circuit boards, heat sinks |

Note: Tinplate sheet gives you rust protection, easy printing, and strong packaging for food, home, and factory items. You can trust printed tinplate sheet to keep things safe, look good, and last a long time.

Tinplate is strong and lasts a long time. It is tougher than aluminum and plastic. The steel inside gives it strength. The tin layer keeps out rust and damage. Tinplate does not break or dent easily. You can stack or move cans without worry. The hot-dip tinning makes a hard shield. This keeps your food safe from harm. Tinplate protects better from bumps and drops than other materials.

| Material | Durability Comparison |

|---|---|

| Tinplate | Stronger, more durable, less likely to break |

| Aluminum | Lightweight, good strength, but less impact-resistant than tinplate |

| Plastic | Generally less durable than tinplate |

Tinplate lasts a long time and keeps food fresh. It blocks air, light, and water. The tin layer stops spoilage and keeps out germs and bugs. You can store and move tinplate cans easily. They stack well and do not crush.

Tinplate is stronger than plastic.

It keeps food safer than aluminum.

The tin layer helps food last longer.

Tinplate has a smooth surface for printing. The tin layer makes it clean and even. Printing ink sticks well to it. You can use many colors and designs. The prints look bright and clear. Hot-dip tinning makes the surface great for printing. Labels and logos stand out in stores.

| Feature | Description |

|---|---|

| Excellent Paintability | Allows for beautifully finished printing using various lacquers and inks. |

| Printability | Enhances the quality of printed products with a bright, clean finish. |

Tinplate keeps printing looking good for a long time. The ink does not fade or peel off. You can handle the cans often and the print stays nice. This is why tinplate is used for food cans and other products that need strong labels.

Tip: Pick tinplate if you want your printing to last and look great.

Tinplate is good for the planet. You can recycle it many times and it stays strong. Its magnetic property makes recycling easy. The tin layer uses safe coatings that follow food safety rules. Most tinplate cans use BPA-non-intent coatings. This keeps your food safe.

| Material | Recyclability Rate (%) | Circular Economy Contribution |

|---|---|---|

| Tinplate | 80–90 | Closed-loop, infinite cycles |

| Aluminum | 65–75 | High, but energy-intensive |

| Plastics | 10–30 | Limited, often downcycled |

Recycling tinplate saves energy and cuts pollution. It uses 60% less energy than making new tinplate. It also lowers air and water pollution. By choosing tinplate, you help the earth and reduce waste.

Tinplate is easy to recycle and sort.

Recycling tinplate saves energy and cuts waste.

The tin layer helps support a circular economy.

Tinplate sheets are helpful for packaging and industry. They are used in food cans, lids, and containers. These sheets keep products fresh and safe. Tinplate sheets block light, air, and moisture. They let you pick custom designs and finishes. This helps brands look better.

How you make and print tinplate sheets is important. Good processes make tinplate sheets last longer. They also help save money and make products more popular.

| Benefit | How It Helps You |

|---|---|

| Corrosion resistance | Keeps products safe and lasting |

| Cost-effective | Saves money and boosts competitiveness |

| Versatile applications | Fits many business needs |

When you use tinplate sheets, remember these tips. Pick the right size and thickness for your product. Choose the best coating for protection and looks. Always check quality standards to get good results.

Tinplate sheets are a smart, safe, and flexible choice. You can use them for packaging or industrial projects.

A Printed Tinplate Sheet is a steel sheet coated with tin and printed with designs or labels. You see it in food cans, paint buckets, and packaging. The printing makes products look attractive and helps brands stand out.

You get strong protection from rust and damage. The smooth surface lets you print bright colors and clear labels. You can recycle Printed Tinplate Sheet easily. Many industries trust it for safe and lasting packaging.

You sort Printed Tinplate Sheet using magnets. Recycling centers melt and reuse the steel and tin. This process saves energy and reduces waste. You help the environment when you recycle these sheets.

Yes, you can. Printed Tinplate Sheet meets food safety standards. The tin coating keeps food fresh and blocks moisture. You see it in cans for soup, fruit, and drinks. The printed surface gives clear product information.

Offset printing works best. You get sharp images and even colors. This method handles large batches and keeps quality high. You can use special inks for heat resistance and durability.

Copyright © 2024 HengYu Aerosol Can. All Rights Reserved. Sitemap | Supported by leadong.com 粤ICP备2024338468号